|

|

Total Site Energy Management |

|||||||||||||||||||||||||

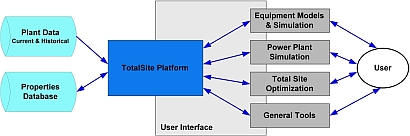

Latest Release: Version 1.0IntroductionOur Total Site Energy Management tool is designed to deal with the problem of how best to supply the steam and electricity needs of an entire plant site. It provides an environment that enables you to simulate, validate, and optimize the energy flows (fuels, steam at various levels, and electricity) in the plant site. There are two main components in the site: the Power Plant(s) – Suppliers and the Process Plant(s) – Users. These two components are linked through site-wide (as well as local) steam headers and electricity grids. The demand for utilities varies with the production capacity of the various plants at the site. Because of the varying cost of fuel and power, and the varying utilities’ demand, the operation of the utility plant needs to be constantly tuned to achieve optimum operation. The Total Site Model is a mathematical model which can model all the interactions in the utility and the production plants and capture the significant potential present here. With this tool you can:

This tool allows you to achieve this by providing a flexible, hierarchical, and user-friendly platform. With this platform, you can:

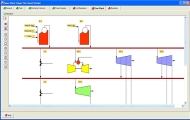

Product Highlights: Core FunctionalitiesAnalysis ToolsThe Total Site Energy Management analysis tools are used to create and analyze models for the power plant unit operations (boilers, steam turbines, process drives, gas turbines, and heat recovery steam generators) based on historical data. The analysis tools also provide direct access to thermodynamic properties of water and steam. These properties are based on the IAPWS Industrial Formulation 1997 of the ASME steam tables (IAPWS-IF97). Simulation ToolsThe Total Site Energy Management simulation tools are used to simulate the performance of individual power plant unit operations, of individual power plants, and of the entire site. These simulations provide insights into efficiencies of operation and can be used to identify and fix general improvements to the current operation. In addition, they can also be used to evaluate and compare the operating costs of several “What-If?” scenarios and help make future planning decisions. The focus is not just on one optimal cost number; instead through these case-studies the software tool can provide additional insights such as:

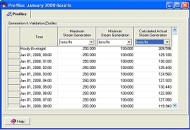

Optimization ToolsThe Total Site Energy Management optimization tools can be used to optimize the energy (steam and power) flows through the entire site at any instant of time or over a period of time based on the operating capacities of the process plants and the operating constraints of the power plants. The optimization tools are used to quantify the operating cost savings that can be obtained from the current operation of the site. They can also be used to evaluate operating cost savings from additional capital investment and the associated trade-offs. The optimization tools also calculate the marginal costs of utilities (all levels of steam and electricity). These costs can be used to make decisions such as whether or not to buy electricity and at what price the electricity contract is attractive. The optimization tools also provide the ability to evaluate how sensitive the optimal operation and the optimal operation costs are to changes in demands of various levels of steam and electricity.

The BenefitsTotal Site Energy Management along with Pinch Analysis address the two important problems that comprise the Total Site Analysis. There are great benefits through the integrated use of these two as, among others, the user can study:

Total Site gives the user an understanding of the energy (steam and power) flows through the plant site. It also gives the user powerful tools to manage the plant site fuel and power consumption. With such a tool, the planning and business decisions for maintaining profitable operation of a plant site become easy. How to OrderTo place an order, or for more information, please contact us by phone, or by email at sales@cwbtech.com. Additional Reading

If you would like to request a copy of any of the above papers, please click here.

|

|

||||||||||||||||||||||||